On November 14-15, Tianlang Qingqing, 2018 polypropylene branch annual meeting and polypropylene industry high-quality development forum was held in Jieyang, Guangdong. More than 180 representatives of upstream and downstream enterprises in the polypropylene industry gathered in “China Yudu” to carry out in-depth exchanges on new developments and new technologies in the polypropylene industry.

As an important support unit and guest speaker of the annual meeting of Polypropylene, Shengbang attended this annual meeting and discussed the development direction and technology upgrade of the polypropylene industry with many elite enterprises in the industry.

Vice President of China National Textile and Apparel Council, Duan Xiaoping of China Chemical Fiber Industry Association, Liu Duanxiong, deputy mayor of Jieyang Municipal People's Government of Guangdong Province, Zhong Jinhong, member of Jieyang District Jiedong District Committee, and Director of Economic Information Technology and Technology Bureau of Jiedong District, Jieyang City Zheng Chuanghui, General Manager of Guangdong Mengtai High-tech Fiber Co., Ltd. Guo Qinghai, General Manager Chen Ciren of Cixi Polypropylene Industry Association/Dadong Chemical Fiber Co., Ltd., and Executive Director of Fujian Sanhong Recycling Resources Technology Co., Ltd. Su Rongqin and other guests were invited to attend the meeting.

Donghua University, Dalian Commodity Exchange, Guangdong Chemical Fiber Research Institute, Beijing Zhongli Machine Engineering Technology Co., Ltd., Changzhou Fubang Chemical Fiber Machinery Factory, Jiaxing Shengbang Machinery Equipment Co., Ltd., China Polypropylene Network, etc. 180 senior experts, scholars, researchers and entrepreneurs gathered in the downstream to discuss the new development of the polypropylene industry.

The conference was hosted by China Chemical Fiber Industry Association, China Chemical Fiber Industry Association Polypropylene Branch, Guangdong Mengtai High-tech Fiber Co., Ltd. and China Polypropylene Network.

As a rising star of synthetic fiber, polypropylene has a relatively small scale, but it has abundant raw materials, simple production process, low energy consumption and low pollution in the production process, and has the advantage of sustainable development. Polypropylene products are characterized by light weight, high strength, acid and alkali resistance, especially in recent years. Functional polypropylene has been developed. The products are widely used in carpets, various ropes, fishing nets, building reinforcement materials, packaging materials and other industrial, household goods and medical Health and other fields. Although China's polypropylene R&D has started late, after nearly 20 years of catching up, China's polypropylene products cover high-strength, anti-UV, dyeable, fine-denier, ultra-fine denier and other differentiated polypropylene products, and have become the world's largest polypropylene producer.

leader's speech

Du Xiaoping, vice president of the China National Textile and Apparel Council and president of the China Chemical Fiber Industry Association, pointed out in his speech that after 40 years of reform and opening up, the chemical fiber industry has created unprecedented profound changes and achieved remarkable results. China has become a global The most complete and largest chemical fiber production, consumption and exporting country in the industry chain. Polypropylene is a small variety in the chemical fiber industry, but it is also an industry with excellent performance and green production process. According to the statistics of the National Bureau of Statistics, in 2012-2017, the actual output of nearly 50 enterprises above the scale of China's polypropylene is stable at around 300,000 tons, less than 1% of the total output of synthetic fibers, which is a small proportion of synthetic fibers. It is mainly distributed in Jiangsu, Zhejiang, Shandong and Guangdong in the southeast coast. Due to the excellent performance of polypropylene, its application in specific fields such as ropes, ribbons, nonwovens, geotextiles, adobes, and high-end sportswear has maintained a steady development in recent years. Compared with the application of foreign polypropylene in industrial and high-end sportswear, this is also the growth point of our future industry. The development of new technologies, new equipment, intelligent manufacturing, Internet +, functional and high value-added products is the responsibility of our new generation of polypropylene people.

Liu Duanxiong, deputy mayor of the People's Government of Jieyang City, Guangdong Province, introduced the industrial development trend of Jieyang City in Guangdong Province in his speech. He pointed out that Jieyang is a manufacturing city in Guangdong and a private economy. It has traditional industries such as metal, petrochemical, textile and garment, food and medicine. Among them, Sinopec and textiles and garments are pillar industries of Jieyang, with a sound industrial chain, including textiles. The output value of chemical fiber clothing reached more than 130 billion yuan. At present, the total investment of 65.43 billion yuan, annual production of 20 million tons of refining + 1.2 million tons of ethylene + 2.6 million tons of aromatics refining and chemical integration, as well as textile printing and dyeing environmental protection integrated processing center and other major projects to accelerate, will certainly drive the realization of petrochemicals and The extension and reconstruction of the chain of the textile and garment industry has also brought important opportunities for the development of the chemical fiber industry and created favorable conditions. In the future, Jieyang will insist on serving enterprises and projects as the top priority, further improve the support measures for private enterprises and small and medium-sized enterprises, comprehensively optimize the business environment, and help enterprises solve practical problems. I hope that this meeting will be an opportunity to focus on major projects, plan cooperation and cut through, create mutual benefits and win-win, and work together to promote the high-quality development of the chemical fiber industry.

High Quality Development Forum

Research and development status and development trend of chemical fiber

Chen Long, a professor at Donghua University, shared the global textile fiber material development strategy and the research direction of Donghua University. The report interprets the US revolutionary fiber and textile program, focuses on system innovation, the close integration of industry, education and research industry chain elements, emphasizes military-civilian integration, textile industry revitalization projects; Japan strengthens the application of high-tech fibers and high-end fiber products, emphasizing functional and The ultimate in performance; German Industry 4.0 Future TEX program, emphasis on low carbon, green, recycling, high performance, functional innovation, composite materials in the new textile materials is the future development trend; and the French Up-TEX plan and the EU Horizon2020 plan. In China's "Guidelines for the Development of the "13th Five-Year Plan for Chemical Fiber Industry", we will position the development status of China's "fiber materials" industry from three aspects: First, it is an important pillar industry for the overall competitiveness of the textile industry. The second is an industry with international competitive advantages. Third, it is an important part of strategic emerging industries. Chemical fiber is no longer only used in traditional textile and clothing. It is actually related to defense, military, transportation, energy, medical and health. In the future, we will focus on fiber new materials, green manufacturing, intelligent manufacturing, and brand cultivation. Finally, it introduces the representative research and development achievements of Donghua University: scientific problems and key technologies of carbon fiber preparation process and its system engineering research; molecular chain conformation control and molding technology research of organic high-performance fiber preparation; molecular design of general fiber Aggregation structure and simulation super-realization research; organic/inorganic nano-hybrid materials and nano-fiber forming basic research; renewable resource fiber material preparation and biomimetic technology research.

Development trend of China's polypropylene industry in 2019

Gao Chunyu, a senior researcher at the Beijing Research Center of Dalian Commodity Exchange, analyzed the current status and development trends of the global olefins market, the global polypropylene market and China's polypropylene market, and listed the main factors affecting the price of polyolefins in 2019. In 2018, the global new ethylene production capacity was 9.12 million tons/year, and the new propylene production capacity was 6.35 million tons/year. In 2019, ethylene production capacity will increase by 5.68 million tons, of which new capacity will increase by 3.3 million tons per year in North America and 1.98 million tons per year in Asia. As capacity growth is faster than demand growth, ethylene production rate may rebound from 2018; In 2019, 3.2 million tons of propylene per year will be added, of which nearly 3 million tons will be added in the Asia-Pacific region. The growth rate will slow down and the propylene operating rate will rebound to 79%.

In 2017, the global polypropylene production capacity increased by nearly 3.7 million tons per year, and the demand growth rate has declined. In 2017, the global demand for polypropylene was 70.70 million tons, an increase of 4.0% year-on-year. The demand growth rate has dropped from 2016, and the operating rate of polypropylene equipment has also declined. It is estimated that by 2020, the world's polypropylene production capacity will reach 84.71 million tons / year, and the demand will reach 76.88 million tons. At present, injection molding, film and wire drawing are still the main applications of polypropylene. In recent years, the demand for polypropylene for drawing and film has been steadily increasing. Other fast-growing applications include pipes, pipe fittings and coating materials. In China's polypropylene consumption, weaving, injection molding and film are the main consumption areas. It is estimated that domestic polypropylene production capacity will be 29 million tons/year in 2019, and demand will reach 29 million tons, up 7.0% year-on-year. It is estimated that the annual output will be about 24 million tons and the net import volume will be about 5 million tons.

The background of the Sino-US trade war and its impact on China's textile industry

Gu Qingliang, a professor at the School of Management at Donghua University, interprets the current textile trade change from the historical perspective of the development of the times. The report introduces the era of global industrial civilization, has passed the first industrial revolution of I-III, is currently undergoing the fourth industrial revolution (4IR), through subversive information and communication technology, quantum technology, artificial intelligence technology, 3D technology, digital Data technology and other deep technology, and its digital laser, material technology, biotechnology, nanotechnology, green technology, robots and other special technologies, open up new application markets, such as carbon fiber structural materials, mobile payment, face recognition, new energy vehicles, Speech recognition, driverless and other applications. China's technological innovation and application leading role in the 4IR industry has emerged. New types of transportation electric vehicles such as internal combustion vehicles, new energy vehicles, unmanned vehicles, high-speed rail and magnetic levitation (opening 600 kilometers in 2020) may become one of the driving forces of the new cycle. Applied to chemical fiber enterprises, the Agreement on Textiles and Clothing (ATC) stipulates that textile quotas will be abolished on January 1, 2005, marking the return of the global textile and apparel trade to the multilateral trading system and entering the post-MFA (multi-fiber agreement) era. The world pattern of major textile and apparel exporting countries has had a huge impact, and China’s textile and apparel exports are facing a new economic environment. China's textile and garment industry plays an important role. Textiles and clothing have been an important source of China's trade surplus for many years. Although China's textile and garment industry exports are affected by unfavorable factors such as the interference of US and European trade frictions, they still maintain a steady growth momentum. At present, the world is in a new era. The inevitable, uneven and inadequate conflicts are the main features. Globalization, trade liberalization is unstoppable, and the inclusive growth of the Belt and Road Initiative is the main task of China's textile industry. Fashion innovation and the creation of China's status are important measures for us to cope with the current world changes.

The road to innovation and transformation of chemical fiber industry in the Pearl River Delta region

Situ Jianyu, deputy director of the Guangdong Chemical Fiber Research Institute, introduced the development of the chemical fiber industry in the Pearl River Delta region. In 1983, Guangdong Province's first full-scale introduction of polyester high-speed spinning production line was successfully put into operation at Xinhui Polyester Factory, which opened the development boom of Guangdong chemical fiber. By the end of 1996, Guangdong had accounted for a quarter of the national output. The full range of products, especially polyester filament yarn, is the first in the country, both in terms of advanced technology and production capacity. With the improvement of the localization of chemical fiber equipment, the advantages of low input and high output of domestically produced equipment are very obvious. The problem of high input and low output in the early stage of Guangdong chemical fiber industry is gradually revealed. The Guangdong chemical fiber industry has been brilliant for more than ten years. Enter the adjustment phase. As China's economic development gradually shifts from the Pearl River Delta region to the Yangtze River Delta region, Guangdong's industrial structure has also begun to change. The tertiary industry has become the largest industry in Guangdong. The chemical fiber industry faces problems such as lack of talent pool, low equipment production efficiency and high cost. Leading to the continued decline of the chemical fiber industry. In the transformation and development of the chemical fiber industry in the Pearl River Delta region, it is mainly reflected in the research and development of product differentiation, deep processing of products and non-woven fabrics. Clothing and apparel is an important direction of industrial transformation. In 2016, the total sales value of Guangdong apparel and apparel industry was 405.767 billion yuan, a year-on-year increase of 2.4%; the export of clothing was 32.732 billion US dollars, accounting for 25.79% of the country. The Guangdong garment industry has maintained a stable operation and continues to maintain its leading position throughout the country. Industrial textiles are an important extension of the chemical fiber industry, and industrial textiles based on non-woven fabrics have maintained a good growth momentum. As a unique branch of the textile industry, it is a short-flow, high-efficiency, low-emissions industry and one of the more active areas of technological innovation. In the province, the industrial agglomeration effect has been gradually improved, and various industrial clusters such as Nanhai medical and health materials, Guangzhou Conghua packaging household materials, Jiangmen geotechnical construction materials, and Dongguan home textile automotive interior materials have been formed.

Structural design, synthesis and application prospects of functionalized polypropylene

Cai Zhengguo, a professor at the School of Materials Science and Engineering at Donghua University, said that polyolefin is a high-molecular material with a large output and a wide range of applications in the world. In 2014, the output reached 140 million tons. However, polyolefins are non-polar polymers, and this inherent defect severely hampers the use of polyolefins in many fields. The introduction of a polar group or a polar molecular segment into a polyolefin molecular chain to prepare a functionalized polyolefin can effectively improve the properties of the polyolefin material, for example, imparting hydrophilicity, colorability, and polarity to the polyolefin. Molecular compatibility, etc., thereby increasing its high added value. Cai Zhengguo introduced the development of polyolefin catalysts and hoped to achieve coordination copolymerization of olefins with polar monomers by designing transition metal catalysts. The realization of this process is very challenging and is considered to be one of the last “Holy Grail” in the polyolefin field. The report focuses on the copolymerization modification of functionalized polypropylene by introducing hydroxyl groups, which effectively improves the mechanical properties, oxidation resistance, thermal stability, light stability and dielectric properties of polypropylene. The application of functionalized polypropylene in polypropylene was shared.

Chemical fiber engineering project specification" polypropylene special research

Wang Min, senior engineer of Beijing Zhongli Machine Engineering Technology Co., Ltd., introduced the research basis, positioning, scope of use and the progress of the polypropylene special project. According to the compilation requirements, the special research work of polypropylene mainly investigated the situation of the production enterprises of the polypropylene project, the supervision of the local government management department on the project establishment, construction and operation of the polypropylene project, the foreign standards and norms of similar projects, and the mandatory in the original regulations. The implementation of the provisions, national laws, regulations, regulations and administrative licenses need to be included in the contents of this code, and sort out relevant laws, regulations, and policies for project construction including public safety, environmental protection, and energy conservation. From this, understand the total scale (project scale), planning layout, and project function, performance, key technical requirements and indicators involved in the project specification; understand the current relevant engineering construction standards and mandatory provisions, and highlight the current mandatory provisions. Coverage, feasibility, operability research; understanding of foreign related laws, regulations, standards research, comprehensive analysis of regulations, norms, standards, constituent elements, terminology, differences between technologies and China, etc. The “Report” and “Draft Engineering Specifications” provide basic data. In the next step, the research report will be prepared according to the research situation, and it is necessary to listen to the opinions of experts from various fields. After the research report is submitted, it is necessary to review and determine the draft of the “Chemical Fiber Engineering Project Specification”.

Finally, the participants discussed with the delegates what aspects of the polypropylene project should be supervised by the government. What should be regulated by the government at each stage of the polypropylene project, which items are unique to the polypropylene project, must be listed separately, and so on.

Application of island composite polyolefin fiber in lithium battery film

Guo Renqi, Director of R&D of Guangdong Mengtai High-tech Fiber Co., Ltd., introduced the technical requirements of lithium battery separators, the production method of lithium battery separators, the preparation of PE-Copet island-type composite ultra-fine denier staple fibers and the fine-denier hollow PP staple fibers. preparation.

PE-Copet staple fiber passes the wet papermaking process and

And PE-Copet non-woven fabric can be prepared by the technology; hollow PP staple fiber can be prepared by wet papermaking process and technology. The PE-Copet non-woven fabric and the PP non-woven fabric are laminated into three layers, and the PE Copet/PP/PE-Copet is thermally stretched by thermocompression bonding to melt and bond the PE layers in the three-layer non-woven fabric together to form a whole. The non-woven membrane, through the alkaline melting agent, melts the Copet in the sea to form a PE/PP/PE three-layer battery separator with micropores ≤ 0.46um. The PP layer has a high strength, high temperature resistance and a high gap rate to maintain a dimensionally stable and complete skeleton. The PE layer has a stable pore size and a radius of less than 0.46 um. The self-closing pores are melted at about 125 ° C, and the self-closing effect is good, which ensures the safety of the lithium battery.

Talking about the Present Situation of Polypropylene Equipment and Suggestions for Intelligent Development

Huang Guofu, general manager of Changzhou Fubang Chemical Fiber Machinery Factory, analyzed the high-speed spinning of many chemical fiber equipment companies such as China Textile Science Research Institute Co., Ltd., Beijing Zhongli Machine Engineering Technology Co., Ltd. and Beijing Shengbang Xinyuan Chemical Fiber Machinery Co., Ltd. Silk and energy-saving polypropylene equipment, and said that automatic material preparation, high-speed spinning and automatic packaging will be the development direction of polypropylene intelligent equipment, which will solve the problem of high labor cost, low equipment occupation, high efficiency, stable quality of finished products and comprehensive cost. Reduce, save energy and increase efficiency. Finally, I shared my experience in visiting the textile machinery exhibition this year. It is pointed out that China's chemical fiber industry is currently at the key stage of transformation and upgrading. From traditional production to intelligent manufacturing, reducing the production cost and labor cost of the chemical fiber industry is becoming an important direction for chemical fiber machinery technology innovation. Therefore, the development of chemical fiber machinery has attracted much attention. The new equipment can make production more efficient and energy-saving, more intelligent, digital operation indicators, online addition of functional masterbatch and finished product inspection, products are more diverse, product defect rate is significantly reduced, fiber quality is further improved and more stable.

A method for rapidly increasing polypropylene spinning equipment to an international level

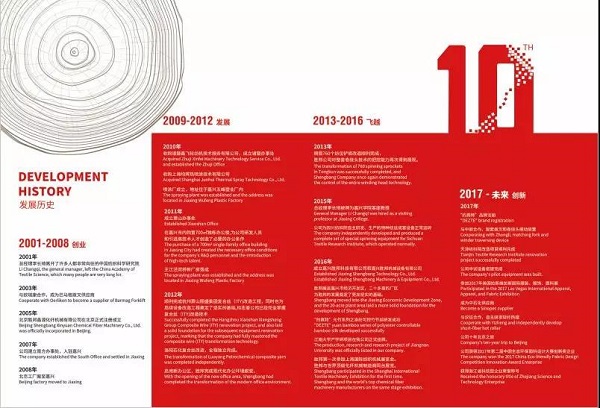

Li Changqi, Chairman of Jiaxing Shengbang Machinery Equipment Co., Ltd. analyzed the changes of the hot roller of the important parts of the winder from 1995 to 2017, the change of the hot roller between 1992 and 2011, and the Toray heat roller from Japan. The quality and the difference between these devices from 1995 to 2011 are beyond doubt. However, due to the low production capacity and the inability to meet the high production requirements of the domestic polyester and nylon markets, many of them have been discontinued in the state of being sold and sold. If these winding heads and hot rolls (especially before and after 1995) are trimmed and modified for the polypropylene market, the level of equipment in the polypropylene market in China will be greatly improved. Early German and Japanese-made wind-up rolls, especially the winder, were more prominent in electrical aging. The universal winder control system developed by Shengbang provides precise control of any winding head on the market. Shengbang can provide a full range of technical services for the major chemical fiber factories in the country, with a complete winding head, hot roll and complete equipment manufacturing capacity.

Polypropylene Enterprise Inventory Management and Optimization

Huang Yangming, technical director of China polypropylene network, analyzed that the data of polypropylene enterprise inventory can not be updated in real time, the labor cost is increased, and the customer service quality needs to be improved. Three aspects are learned from the three aspects of storage, material use and warehouse management. Do inventory management. It is pointed out that the bar code management can be realized by using the invoicing and scanning code software to improve the speed of entering the documents. The bar code gun can directly scan the inbound and outbound files, and basically can input a product in 1-2 seconds. At the same time, the accuracy can be improved, and the barcode scanning can accurately identify the goods and avoid artificial selection or input errors. Invoicing software has become a key tool for modern managers to help them manage their invoicing business, and is also the key to improving business efficiency.

In the same period, it also held 2018 polypropylene industry chain high-quality development achievements display, Guangdong Mengtai High-tech Fiber Co., Ltd., Zhejiang Jincai New Materials Co., Ltd., Jiangxi Donghua Machinery Co., Ltd., Jiaxing Shengbang Machinery Equipment Co., Ltd., Shenzhen Zhongtianxin Textile Technology Co., Ltd., Changzhou Fubang Chemical Fiber Machinery Factory, Guangzhou Junte Chemical Co., Ltd., Yancheng Ruize Masterbatch Co., Ltd., Yancheng Xinle Machinery Technology Co., Ltd. demonstrated the company's technological achievements, development concepts and strategic planning. .

As the support unit of this annual meeting, Shengbang is very honored to participate in it and share its practical experience of development and innovation to help its peers broaden their horizons and inspire ideas.

Through this annual meeting, Shengbang will continue to improve its innovative development mechanism and production technology, and provide customers with more excellent chemical fiber machinery products with special creativity and first-class professional quality. New developments in the industry and new areas of application for more applications, dedication to the new role of Shengbang!